Our fully-automated crystal growth control system offers complete control over every phase of the process of crystal growth, from seeding, necking, shouldering, and equal diameter growth all the way to finishing. This can provide a strong guarantee on both the consistency of crystal bars and the stability of products.

We use high-precision cutting machines to process external and internal cylinders, which in turn contributes to a high level of production efficiency and ensures our products can be cut to high dimensional accuracy. This accuracy has led to numerous customers coming back to us time and again, knowing they will be getting the best possible products. Red laser light diffraction is carried out for testing a wide range of optical materials. With the use of single-shaft polishing machine and optical rolling machine, we can shape the square materials into round cylinders. This guarantees a small tolerance, high pass rate and superior efficiency.

We can grind our products to the required size, perpendicularity and parallelism according to the customer’s order. The laser crystal bars, which are available in various sizes, are precisely ground in a single run for increased production efficiency.

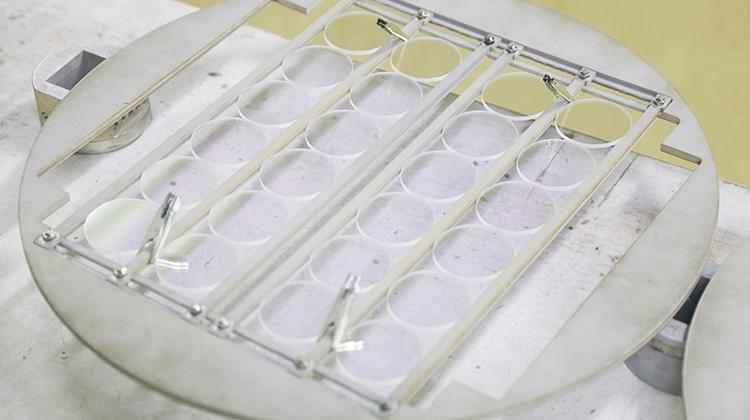

We have invested in more than 20 sets of 4-shaft polishing machines which can perform laser polishing on the end face of the laser crystal with high levels of accuracy and efficiency.

The industrial grade ultrasonic cleaning system is utilized to ensure the uniform cleanliness of all workpieces. Prior to coating, cleaning and wiping need to be carried out in order to ensure the smoothness of the coated laser crystal meets specification requirements. Our company has introduced high-performance coating machines from different countries. These facilities, combined with IAD and EB coating techniques, can adapt to a variety of application requirements.

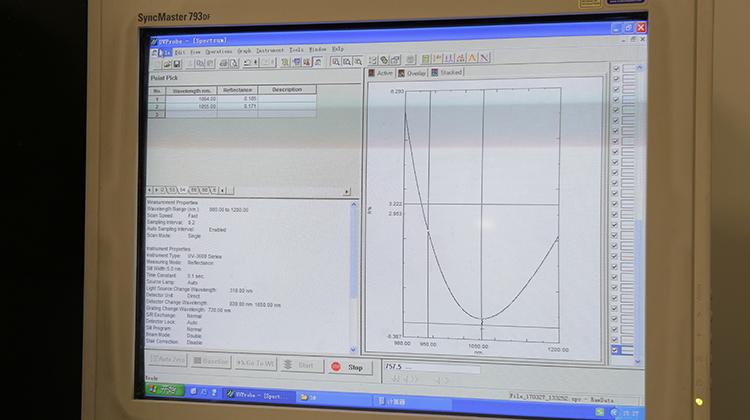

In this workshop, we own a host of cutting-edge optical test facilities. One example of our test facilities is the spectrophotometer that comes from Japanese Shimadzu. We take strict measures to ensure the quality of our products.

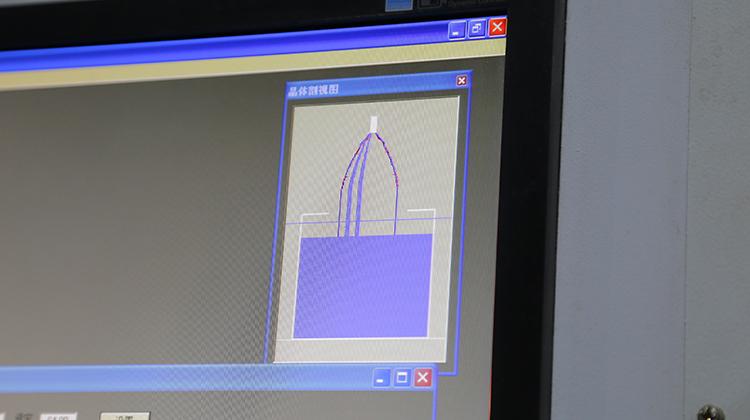

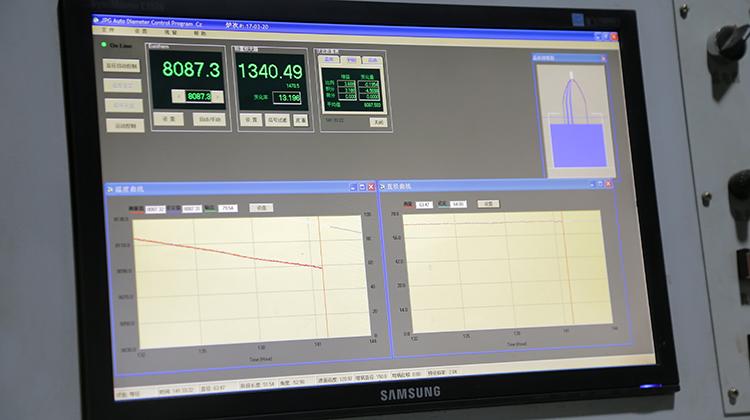

Single-crystal growth Furnaces

The crystal growth control system is fully automatic, which means that from the initial seeding stages, through necking, shouldering and equal diameter growth, all the way to finishing, are automatically controlled. This ensures the consistency of the crystal bar, and guarantees the stability of all products.

Real-time microcomputer single crystal pulling growth control system

The swing phenomenon that occurs in the operation of a single crystal furnace rotary and pulling system is both modeled and numerically simulated. This ensures the primary growth process of the YAG crystal become automatic, which increases both the growth quality and yield of the products.

Round cutting machine

We use diamond saw blades to achieve high speed cutting. In addition to straight cutting, simultaneous long and square stocks cutting, it can also cut prism blanks at specialized angles. The high production efficiency is favorable for massive production.

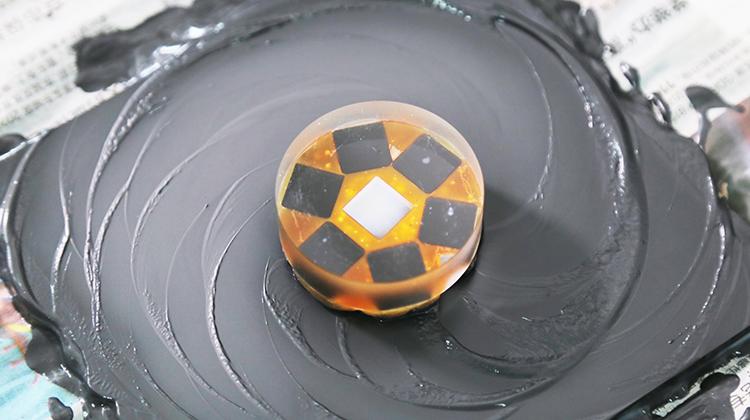

Material selection by testing the diffraction spot of the red light laser

This method allows the parallel laser to penetrate into the interior of the crystal. Different materials are chosen by observing the ovality of the diffraction spot by placing a round circle at the light outlet.

We use the laser to guarantee that all the crystals chosen from the blank material are free of cores or side cores.

Inner circle cutting machines workshop

We use the rolling bearing of vertical spindle structure, which has a rigid, precise and unshakable axis and feeding system with a stepper motor and motivation to drive the module in order to guarantee the stability and precision of the system.

The operation of high precision inner circle cutting machines.

Laser crystal cutting process

Single axis grinding and polishing work area

Single axis grinding and polishing machines grind square stock into prismatic shapes

Measure the circular degree of the laser crystal

First grind the products from a square shape to a polygon shape, and then barrel them from prismatic to a cylinder in a single run. The key factors are precision and yield. A small tolerance guarantees high yield and high efficiency.

Working area of optical rolling machine

First grind the products from a square shape to a polygon shape, and then barrel them from prismatic to a cylinder in a single run. The key factors are precision and yield. A small tolerance guarantees high yield and high efficiency.

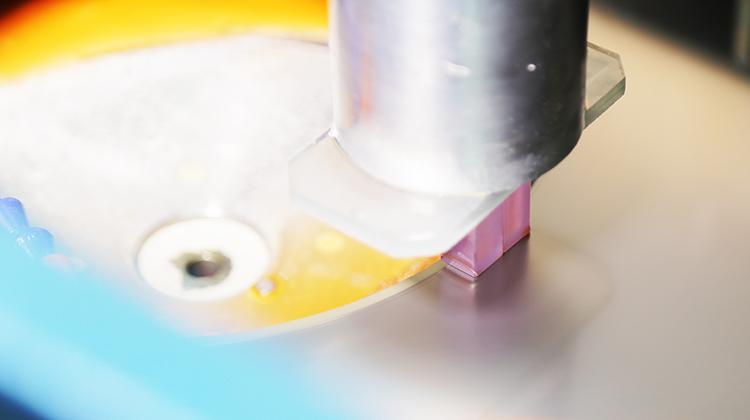

Laser crystal under rolling operatio

Final slight adjustment of the cylinder laser crystal after the reshaping from the machines.

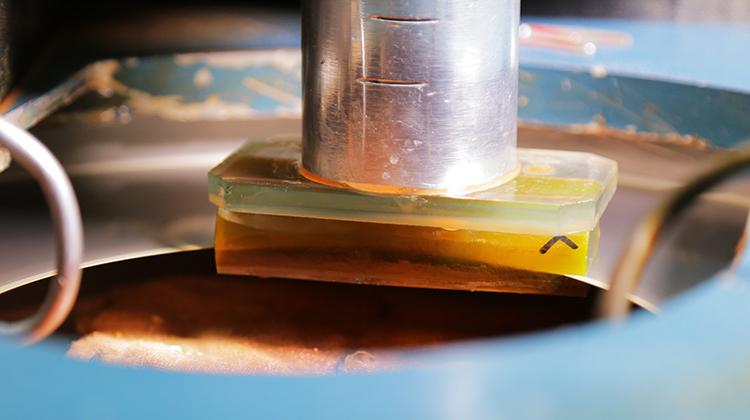

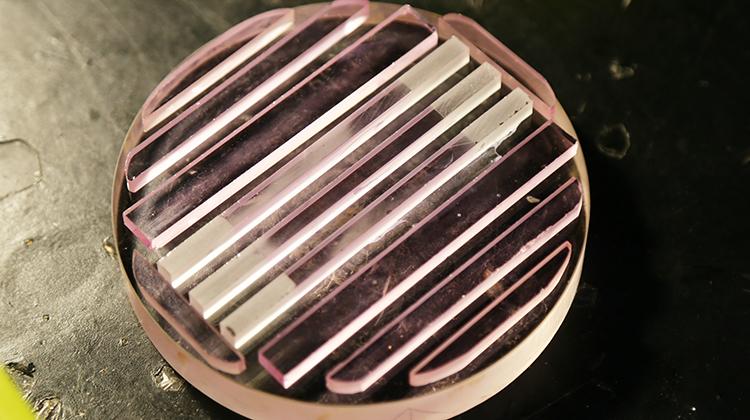

Fine grinding of the upper plate with Q-switched crystal viscose

We provide products in specific sizes, surface shapes and parallel degrees according to customer requirements.

Fine plate grinding of the bond plate photoresist

Fine plate grinding of the laser crystal

The laser crystal bars, which are available in various sizes, are precisely ground in a single run to raise the production efficiency.

Measure the verticality of the laser crystal

Fine grind and measure the verticality of the laser crystal before polishing.

We own more than 20 four-axis polishing machines. These machines polish the surfaces of laser crystals at a laser level with a high accuracy and high efficiency. This ensures each optical production is done within strict processing specifications.

Polishing performed by four-axis polishing machines

Self-inspection of flatness while polishing in order to guarantee that the flatness meets customer requirements.

Self-inspection of the parallelism during polishing guarantees the parallelism precision meets customer requirements.

Ultrasonic cleaner at an industrial grade

The ultrasonic cleaner ensures an excellent washing effect, and high efficiency, as well as high and unanimous hygienic standard for all the workpieces.

Ultrasonic cleaner in operation

Laser crystal after ultrasonic cleaning

The cleaning of the laser crystal prior to coating

The cleaning process ensures that the smoothness of the laser crystal meets the required standards.

Laser crystal with extremely fine finish after scrubbing

Coating workshop

We own numerous coating machines from both at home and abroad. Our IAD and EB coating techniques guarantee that our products meet various application requirements.

New cologne coating machines imported from Japan

Firm and well-sealed film,

High light resistant damage threshold,

Stable quality.

Spectrometer UV3600 from Shimadzu, Japan

We use a Spectrometer UV3600 from Shimadzu, Japan, which is able to measure the spectrum of the optical samples ranging from 190nm to 3300nm.

Coating, transmitting ratio of Q-switched crystals graphs

The inspection staffers are cleaning and testing the surface smoothness of the laser crystal and laser lens before leaving the factory.

The quality control staffers are inspecting the smoothness of the laser crystal with the microscopes.

Laser lenses to be tested

Laser lens

Finished products with package

Vacuum packing ensures the products are protected from dampness, mold, pollution, and oxidation. The packaging also saves space, shipping costs, and extends the storage life.

Beijing Jiepu Trend Technology Co., Ltd.

Add.: Room 8303, No.8 Building, Yongchang Industrial Park, No.3, Yongchang North Road, Beijing Economic and Development Area, Beijing, China

Zip Code: 100176

Tel.:

+86-10-67877187

+86-10-67875695

+86-10-67867245

Fax: +86-10-67877162

Skype: amy_laser

Email:

marketing@jiepu.com